Digital Inspection opens the way to better Tracking, Reporting and Communication for Ken’s Foods

Isaac Serbin, is the Environmental Health & Safety Manager for the facility in Indiana. He ensures the people, product and facility are kept safe so their product continues to flow to your table. When Ken’s Foods’ facility had an increase in forklift accidents, Isaac took notice.

It was the start of the pandemic and uncertainty ran high. As workers in the facility were concerned with the unknown, forklift drivers were unfocused. Distractions were the main cause of the accidents, and he knew he needed to find a solution to support the forklift driver’s efforts.

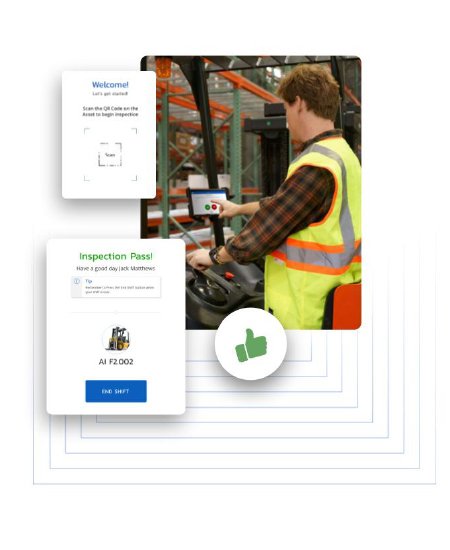

During Mr. Serbin’s search for a safety solution, he found the SIERA.AI S2 Digital Inspection with Impact Monitoring. The S2 was going to help him accomplish multiple problems at the same time.

14%

of inspections recorded, failed

73

reports of “Unauthorized Access”

Problem:

Forklift operators skip the forklift inspection before their shift. As this is an OSHA violation, its critical to stop and change the behavior.

Forklift operators skip the forklift inspection before their shift. As this is an OSHA violation, its critical to stop and change the behavior.

Solution:

The S2 captures the forklift operator and the forklift with a visual. With the operator’s understanding, the goal is to change past behaviors in order to ensure their safety and OSHA compliance. Each operator is accountable to perform the shift inspection.

The S2 captures the forklift operator and the forklift with a visual. With the operator’s understanding, the goal is to change past behaviors in order to ensure their safety and OSHA compliance. Each operator is accountable to perform the shift inspection.

Download the Case Study

Fill the details below to download the detailed case study.