Scout has given us the control we need to ensure our lift trucks are OSHA compliant and running efficiently. The simple scan – answer format makes it fast and easy for the workers to use and report issues with pictures to pinpoint problem areas.

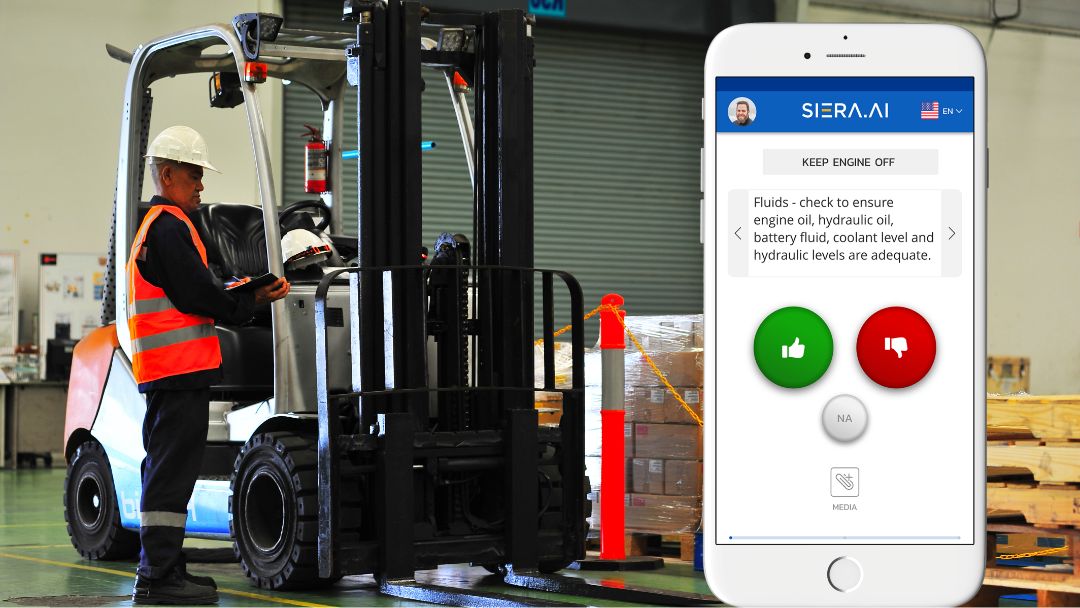

Owens Corning Switches from Paper Forklift Inspection Forms to Digital Inspections

Owens Corning provides innovative products, manufacturing technologies and sustainable solutions that address energy efficiency, product safety, renewable energy and durable infrastructure. Not only does Owens Corning make products that are forward-thinking, but everyone in the company works toward these standards as well.

Mr. Davis is the EHS Leader of Environmental Health & Safety functions for all plants in the U.S. and support for International. Mr. Davis was searching for a way to resolve inconsistencies in the inspection and reporting for the lift truck fleet.

Digital Inspection Checklist Goals

Currently, the lift truck operators conduct paper-based OSHA and safety inspections on the forklift. This dated practice had numerous challenges including missed inspections, inaccuracies, lack of communication and hard to track paper for problem areas. Mr. Davis decided to search the marketplace for a digital solution that achieves two main goals:

1. Track compliance at the operator level and

2. Identify equipment issues quickly.

Searching for a solution wasn’t easy. Mr. Davis had evaluated numerous solutions over the years, unable to find the right fit. A reference from another department brought SIERA’s Scout to his attention. During the demonstration it was quickly realized the flexibility and applicability of Scout. Mr. Davis and his team were able to maintain their proven processes and the vital content on the checklist. If changes need to be made moving forward, it’s quickly and easily done in the Cloud.

Mr. Davis’s team provided the necessary information for a fast implementation and in just 1 day, Scout was ready to go.

Accurate Data Collection

Today, the forklift operators use their Smartphones to scan the QR code on the lift truck, scan in their badge or enter in their employee PIN and begin answering the critical inspection questions. To keep things fresh, all questions and answers are presented in random order. This ensures the operator is reading each question fully and completely for accurate data collection. Additional space for notes as well as picture attachments can be included for clarification.

If a problem on the forklift is detected, a notification is immediately sent to Mr. Davis. As he reviews the level of complexity of the failed report, maintenance is also notified and can begin the repair process minimizing downtime.

All inspection results are immediately available in the cloud-based, real-time Dashboard. The metrics allow Mr. Davis to quickly know the status of an asset allowing him to act immediately if a forklift needs repair or out of compliance.

- Transforming paper to digital checklists means improved visibility of asset condition

- Immediate notification of failures.

- Ability to attach pictures and notes for greater communication of problems or failures

- Assured OSHA compliance

- Greater transparency has the ability to improve the asset’s end of life expectations

- All checklist data collected is stored in the cloud for easy access, lookup, and analysis

What’s Next…

Moving forward, all new lift truck operators will immediately begin using Scout. In addition, maintenance managers will also adopt Scout for plant equipment inspections for safety and maintenance ensuring maximum efficiency and energy consumption.